- Home

- Why Us

- Safety Nets

- Balcony Safety Nets

- Kids Net For Balcony

- Pets Safety Nets

- Grill Balcony Safety Nets

- Terrace Top Nets

- Industrial Safety Nets

- Building Safety Nets

- Duct Area Safety Nets

- Open Area Safety Nets

- Staircase Safety Nets

- Construction Safety Nets

- Swimming Pool Safety Nets

- Monkey Net For Balconies

- Car Parking Safety Nets

- Coconut Tree Safety Nets

- HDPE Nets , Nylon Nets

- Bird Nets

- Sports Nets

- Contact Us

HDPE Nets , Nylon Nets

- Home

- HDPE Nets , Nylon Nets

LR Safety Nets

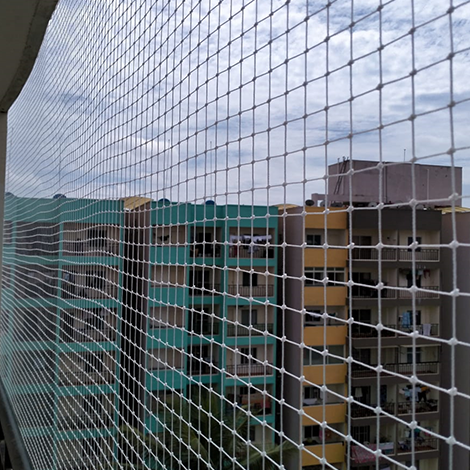

HDPE Nets , Nylon Nets

HDPE (High-Density Polyethylene) Nets and Nylon Nets are two prominent materials utilized across various industries due to their unique properties and applications.

HDPE Nets, composed of high-density polyethylene, offer exceptional durability and strength while being lightweight and easy to handle. They are known for their resistance to UV radiation, making them suitable for outdoor applications where prolonged exposure to sunlight is common. HDPE nets find extensive use in agriculture for crop protection, shading, and packaging. Additionally, they are employed in aquaculture for fish farming, construction for safety netting, and packaging industries due to their cost-effectiveness and versatility.

+91 8886171492

On the other hand, Nylon Nets are made from nylon, a synthetic polymer celebrated for its high tensile strength, elasticity, and abrasion resistance. Nylon nets exhibit excellent resilience and durability, making them ideal for demanding applications such as fishing, sports, and industrial usage. In fishing, Nylon nets are widely used for their ability to withstand the rigors of marine environments and resist abrasion. They are also prevalent in sports facilities for goals, barriers, and backstops, where strength and durability are paramount.

When deciding between HDPE and Nylon nets, it's essential to consider the specific requirements of your application. HDPE nets are preferred for their UV resistance and affordability, making them an excellent choice for outdoor applications. Meanwhile, Nylon nets excel in situations requiring high tensile strength, elasticity, and abrasion resistance, making them suitable for heavy-duty applications in fishing, sports, and industrial settings. In summary, both HDPE and Nylon nets offer distinct advantages and are selected based on the particular needs of the application. Whether you require UV resistance, cost-effectiveness, or superior strength and durability, choosing the right netting material will ensure optimal performance and longevity in your specific application.